Apron Feeder Design

We offer troubleshooting assistance and design assistance to all our clients. Ii Design Criteria All design should be based upon a reasonable TI Traffic Index provided by a traffic engineer.

Apron Feeders Meka Concrete Plants

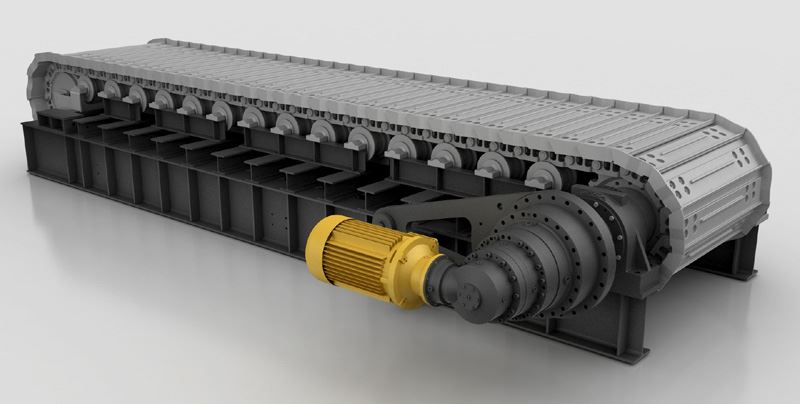

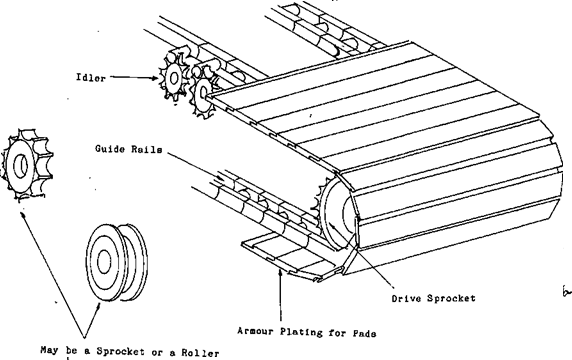

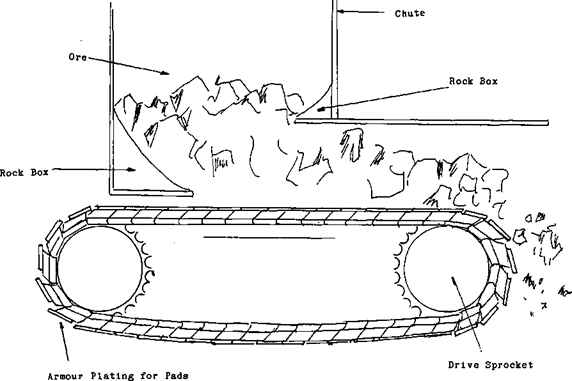

Apron feeders are designed to feed material at a desired volumetric rate to downstream equipment and convey material on a series of overlapping pans attached to multiple strands of a heavy tractor crawler-type chain.

. Apron feeders Groundbreaking excellence in design Metsos heavy duty and robust apron feeders are engineered and built with an intense commitment to quality and attention to detail providing maximum uptime and many years of service life. We are here to provide technical services as well as practical solutions for the most demanding situations. Each of our pans is manufactured identically due to our casting method and our use of jigs and gauges.

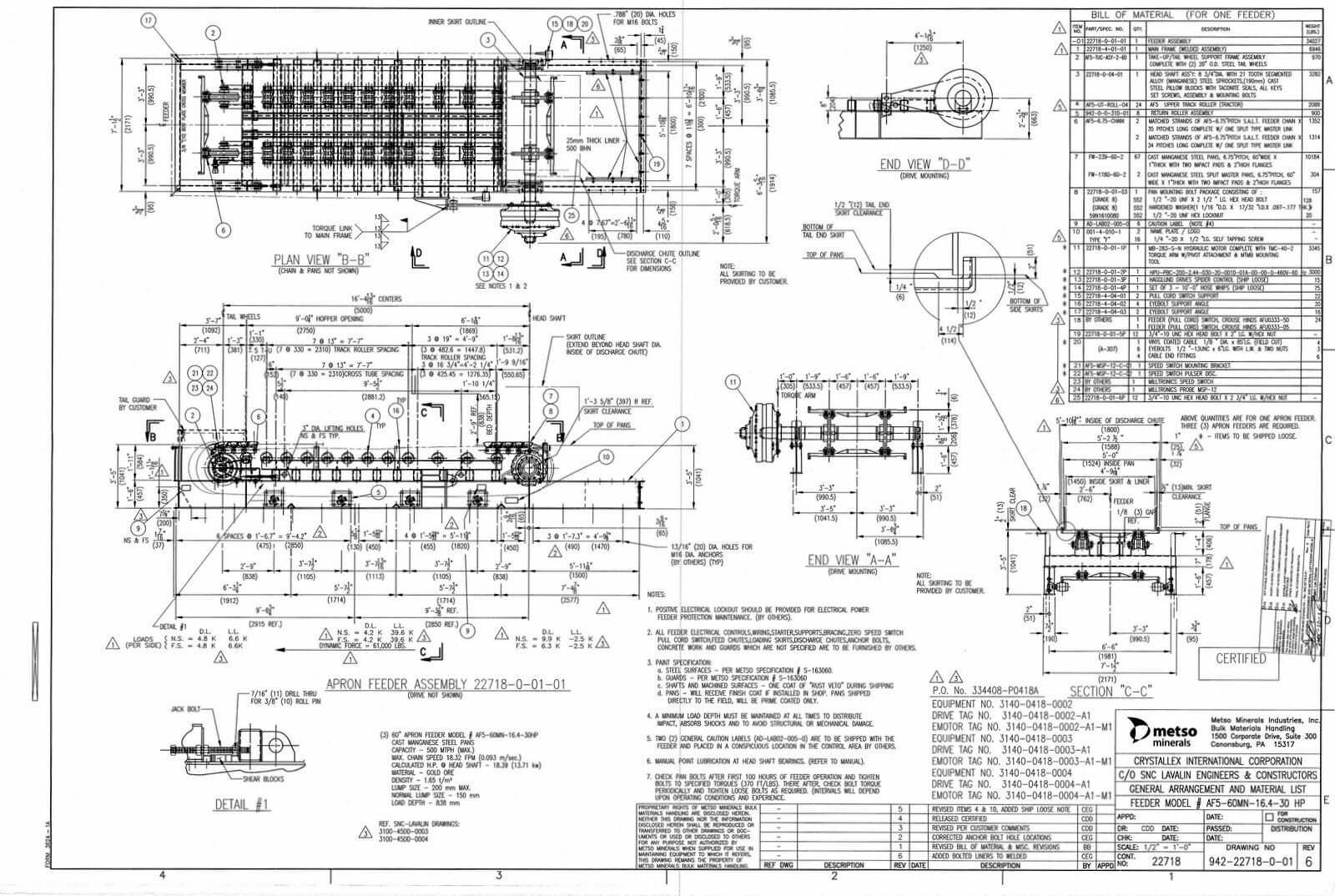

The methods for determining feeder loads and. Max slope of Apron Feeder profile degree 0 CapacityWorking Qw MTHr 2000 Design capacity Factor 125 Capacity design Qd MTHr 2500 Material. The Rexnord design and engineering team will review specifications and recommend the best option for your application.

In order to cover widest range of capacities all types of Caterpillar crawler under-carriage heavy-duty chains can be used. Whatever the material to be moved the best method will be found with the complete line of Rexnord Apron Feeders. The need for feeders and mass-flow hoppers to be designed as an integral unit to promote uniform feed is emphasised.

A feeder is an extremely important element in a bulk material handling system since it is the means by which the rate of solids flow from a bin or hopper is controlled. Their reliability has been tested by hundreds of Apron Feeders still operating in the field. Basic objectives for uniform draw-down an overview design and performance focussing on of feeder belt and apron feeders is presented the importance of correct for unrform draw-down with a fully active hopper outlet the ca- hopper and feeder interfacing is stressed the objective is to pacity of the feeder must progressively increase in the.

Look to Rexnord for the right answer to bulk material feeding solutions. Stationary single-shaft impact crusher right fed by two apron feeders. These innovative apron feeder design possess cutting-edge inventions in their designs that make feeding mining ores and other products to the mining mill straightforward.

Ad Best Deals On Apron Feeders. The pavement section must be designed to accommodate a LACFD design vehicle 75000 pounds as well as the standard Caltrans design vehicle. Driveway aprons vary in length from about eight to 15 feet starting at the street and measuring toward the house.

Apron feeders are built with heavy duty frames track chains and cast manganese pans. The limestone crushing system consists of a GBZ200010000 heavy-duty plate apron feeder and a PCF2018 single-stage hammer crusher. How to Design Efficient and Reliable Feeders for Bulk Solids by John W.

And Greg Petro PE. 6 Apron feeders always need variable speed drive. The basic design features of belt and apron feeders is presented.

Our apron feeder pans for all makes of feeders are designed jigged and tested for superior fit. Lump size Normal mm 400 Lump size max mm 400 Moisture content 20 Fines content 40 Bulk Density vol. We custom build our apron feeders based on material capacity load and geometry.

ϒ1 tm3 08 Bulk Density Load ϒ2 tm3 12 Angle of repose α degree 37 Volumetric. Because mining processes vary with companies the apron feeder design come in a very diverse selection that holds distinct sizes shapes and models to ensure all shoppers. IEM apron feeders are robust in design and built for heavy loads and high impacts.

So maximum of variable speed range should correspond to design capacity which could be about 20 more than the guaranteed capacity. Extreme Heavy-Duty Apron Feeders type BPB-SF Design details Drive shaft with hardened sprockets. Get the Deals now.

MMD Apron Plate Feeder - Direct Loading Demonstration Heavy Duty Design Due to its strength and impact resistant design the feeder has the versatility to be loaded by various methods from trucks to draglines. The apron feeder is composed of undercarriage components tail head shaft flights frame and a drive. The segments can be changed without opening of the chain.

Apron Feeder Design Calculations Frequently Asked Questions We Offer Advice IEMs success comes from sharing our expertise. Economic Apron feeders are available in a standard range. No matter the duty Apron feeders will be available to keep your operations running smoothly with increased uptime.

Its reliability and robustness have proven to give many years of trouble free operation. Apron feeder RKF 22 x 158 - D8 with inboard chain Apron feeder RKF 34 x 170 - D9 with outboard chain Apron feeders are designed for conveying capacities of more than 14000 th and can be integrated into stationary semi-mobile or mobile plants. The Industrys most preferred feeder.

Our robust design makes our apron feeders a truly economic and reliable material handling solution for increasing uptime and overall efficiency. Highest dimensional accuracy ensures proper articulation with industry leading gap minimization. McLanahan Apron Feeders are designed based on a decades-old concept developed by National Iron Company of using a crawler undercarriage into an Apron Feeder.

Since the apron is. AASHTO design manual or applicable manufacturers design specifications. That means apron feeder will normally run below maximum range by certain margin.

The designed production capacity is 500 th but the actual production capacity is less than 400 th. Order today with free shipping. The essential requirement is to promote uniform feed with the whole of the hopperfeeder interface active.

Generally the apron feeders are installed under the opening at the discharge end of the hopper. This provides room for selection of speed during field trials setting. Over time the design of apron feeders has improved owing to the robust nature of the cement and mining industries.

Ccrb Mining Apron Feeder Manufacturer Ec91120309

An Expert Insight Into Apron Feeder Evolution Quarry

0 Response to "Apron Feeder Design"

Post a Comment